Why Nylon Outperforms Other Synthetic Polymers in Industrial Applications

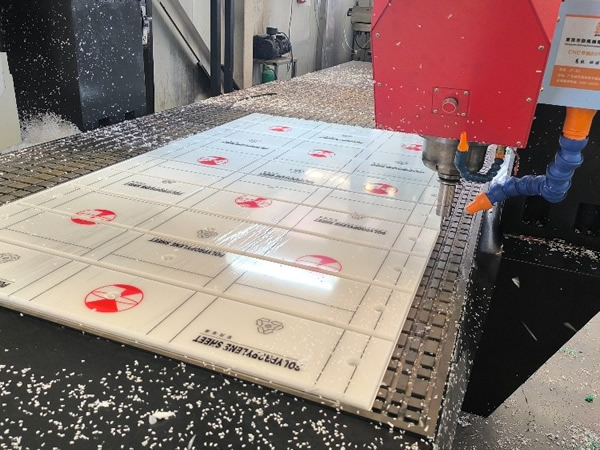

Selecting the right synthetic polymer for mechanical equipment is critical. While alternatives such as Ultra-High Molecular Weight Polyethylene (UHMW), High-Density Polyethylene (HDPE), and Polyoxymethylene (POM) are available, nylon consistently demonstrates superior performance in key industrial applications.

-

Nylon vs. Ultra-High Molecular Weight Polyethylene (UHMW):

Although UHMW is known for its wear resistance, it lacks the structural rigidity required for high-stress applications. Nylon offers an optimal balance between abrasion resistance and structural strength, making it ideal for load-bearing components. -

Nylon vs. High-Density Polyethylene (HDPE):

HDPE provides good chemical resistance but is prone to deformation under high temperatures and heavy loads. Nylon excels in these conditions, offering superior thermal stability and strength. -

Nylon vs. Polyoxymethylene (POM):

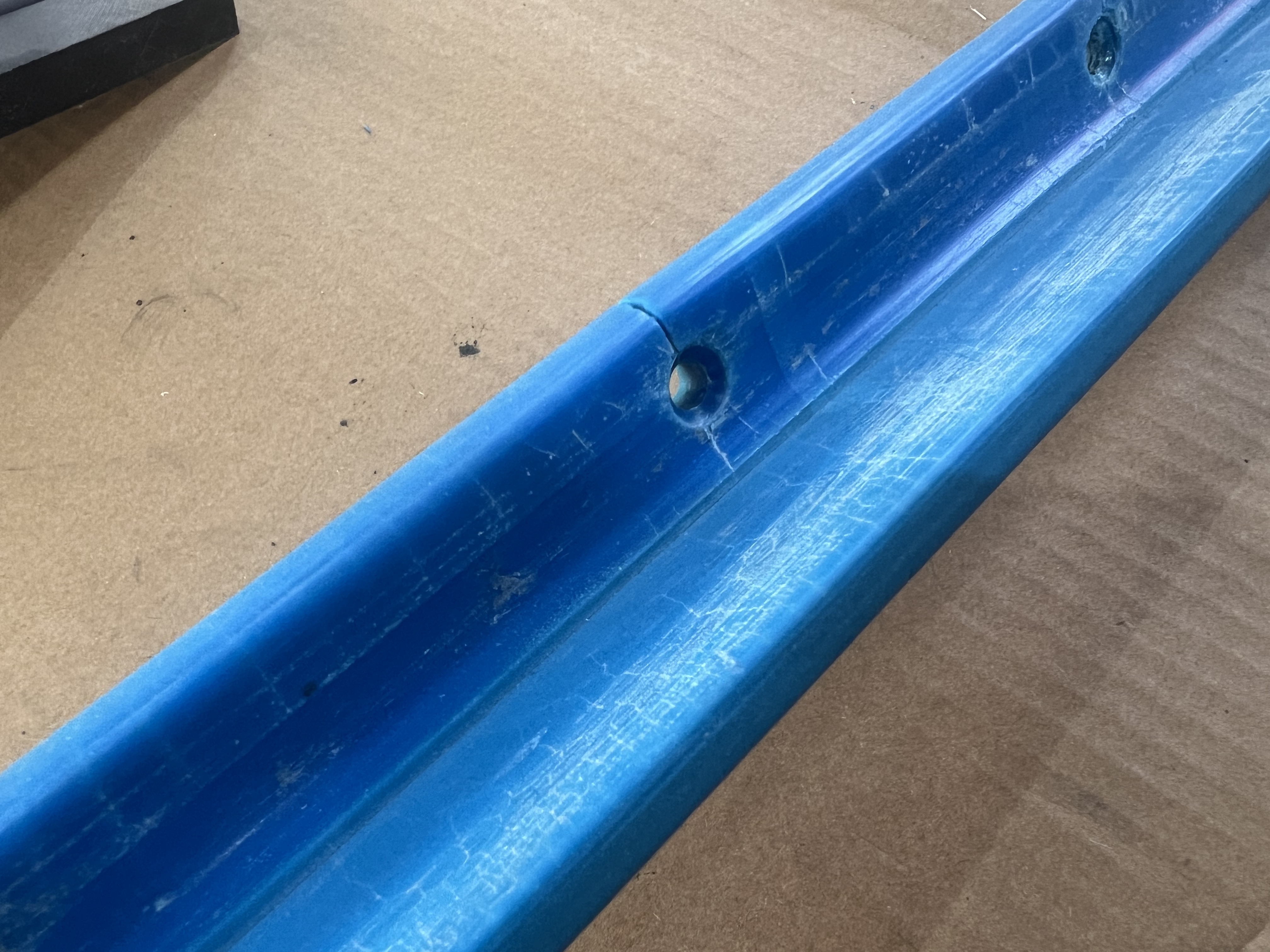

POM is favored for its low friction, but its impact resistance falls short compared to nylon, especially under repeated dynamic stress. As a result, nylon is better suited for environments exposed to vibration and mechanical shock.

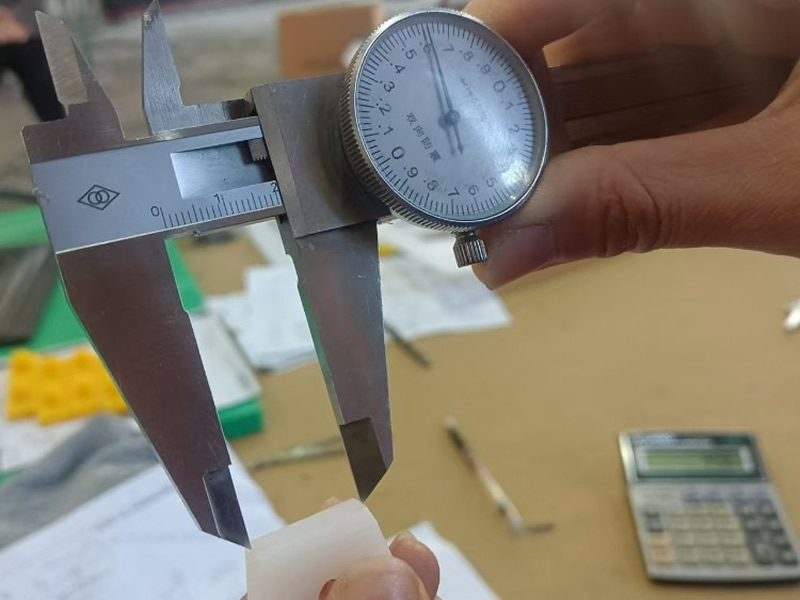

A real-world example highlights nylon’s advantages: a robotics manufacturer faced frequent premature failures in joint components made from POM. After switching to precision-engineered nylon blocks, the company achieved a 20% improvement in joint stability and significantly reduced equipment downtime. This change underscores nylon’s exceptional performance in demanding industrial settings.

For reliable, durable, and high-performance polymer solutions, nylon remains the material of choice.