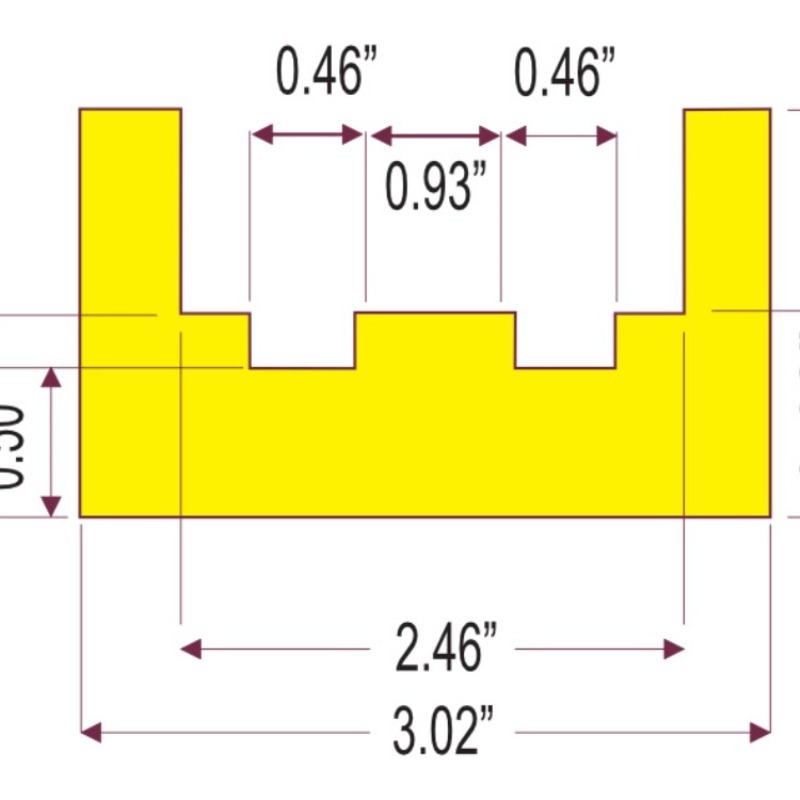

| Thickness(Inch) | Thickness(MM) | Application |

|---|---|---|

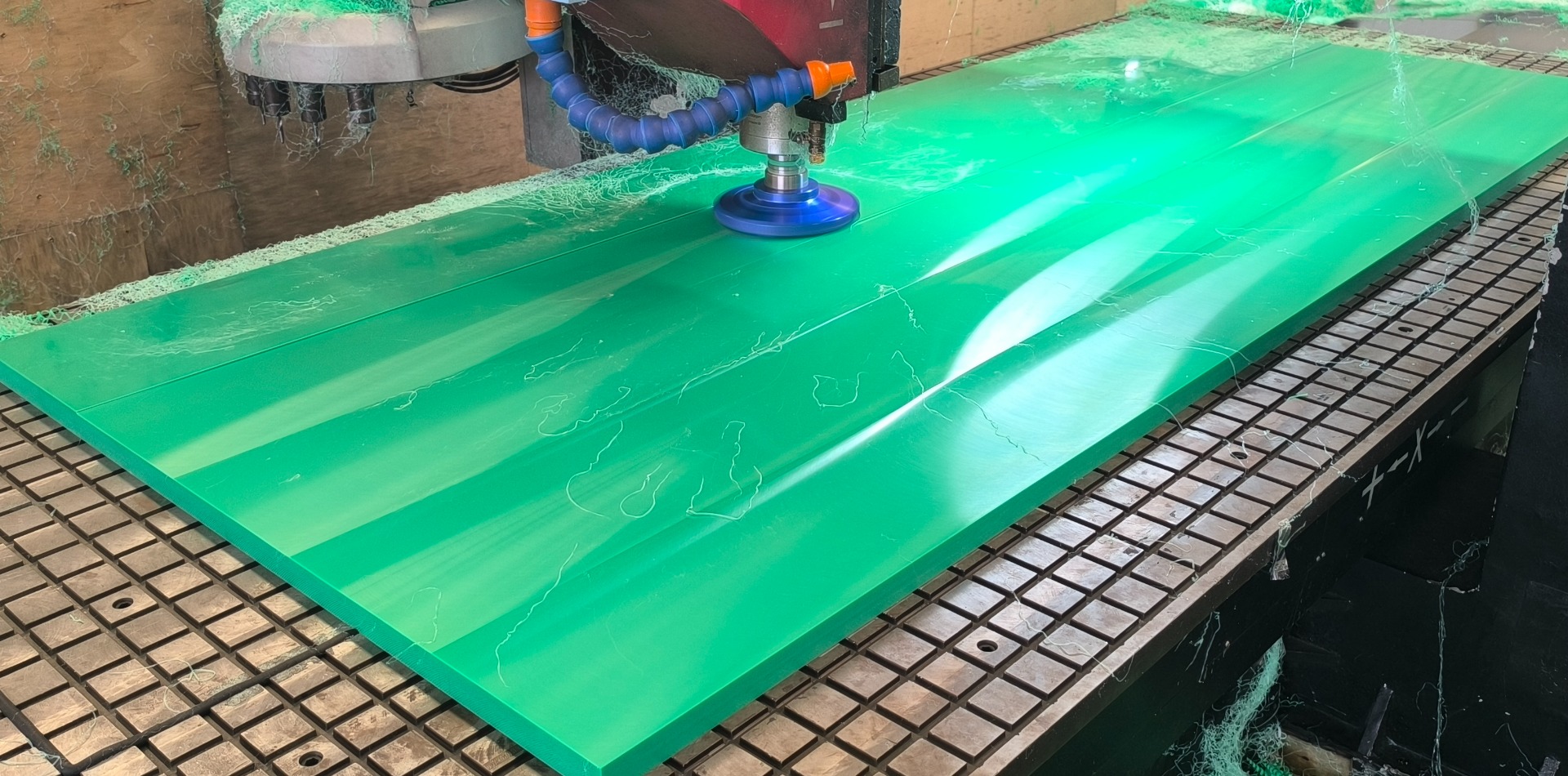

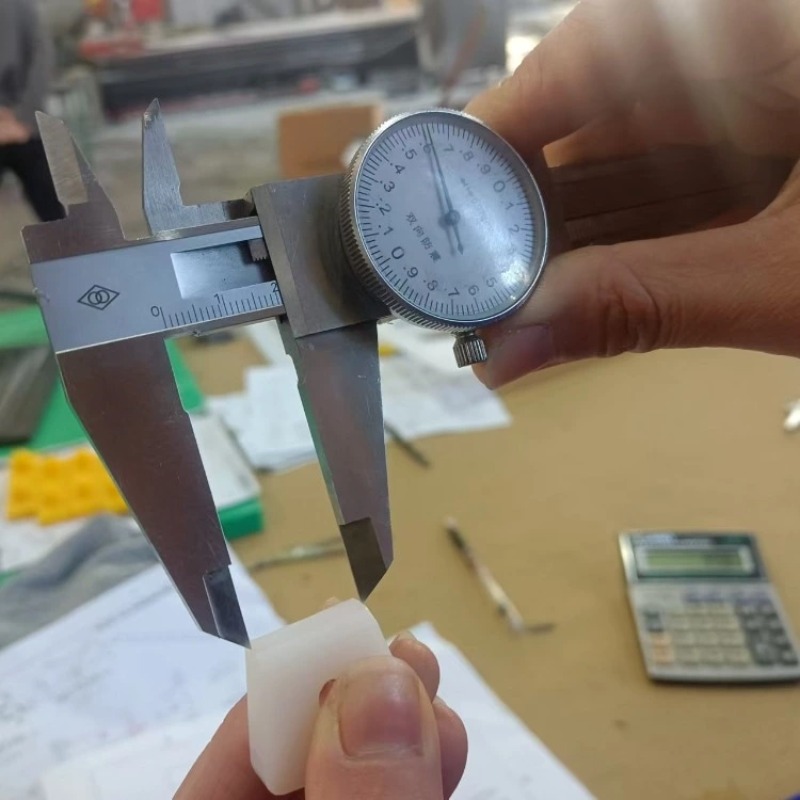

| 1/8'' | 3.175mm | Flexible And Thin, Mininal Friction ,High Precision ,Guiding Systems,Rail lining,and Light weight Machinery Components |

| 1/4'' | 6.35mm | Added Durability,No Selfied Flexibility,Mid-load Applications,Light-duty Conveyor Parts,Packaging Machinery,Protective Lining |

| 3/8'' | 9.525mm | Balance Between Thickness and Flexibility ,Agricultural Machinery Linings,Conveyor Chutes,And Sliding Surfaces Inlight Industrial Equipment |

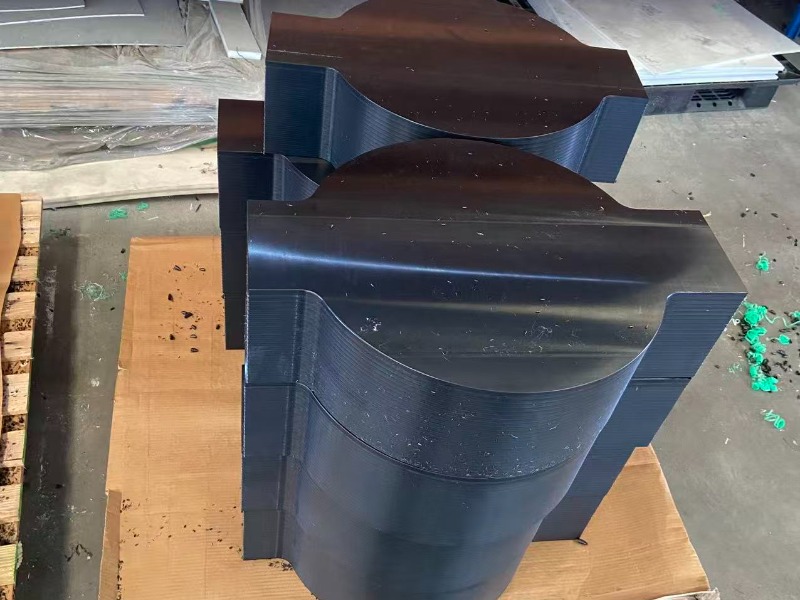

| 1/2'' | 12.7mm | As Standard Industrial Thickness,Used In Heavy-duty Conveyor Systems,Cutting Surfaces,And Machinery Parts |

| 3/4'' | 19mm | Equipment Liners,Protective Guards,Structural Components |

| 1'' | 25.4mm | Loading-Bearing Surfaces,Heavy Equipment Liners,Impact-resistant Barriers,Maxmum Strength In Protection And Longevity |

| Grade | Description | Standard Colours |

|---|---|---|

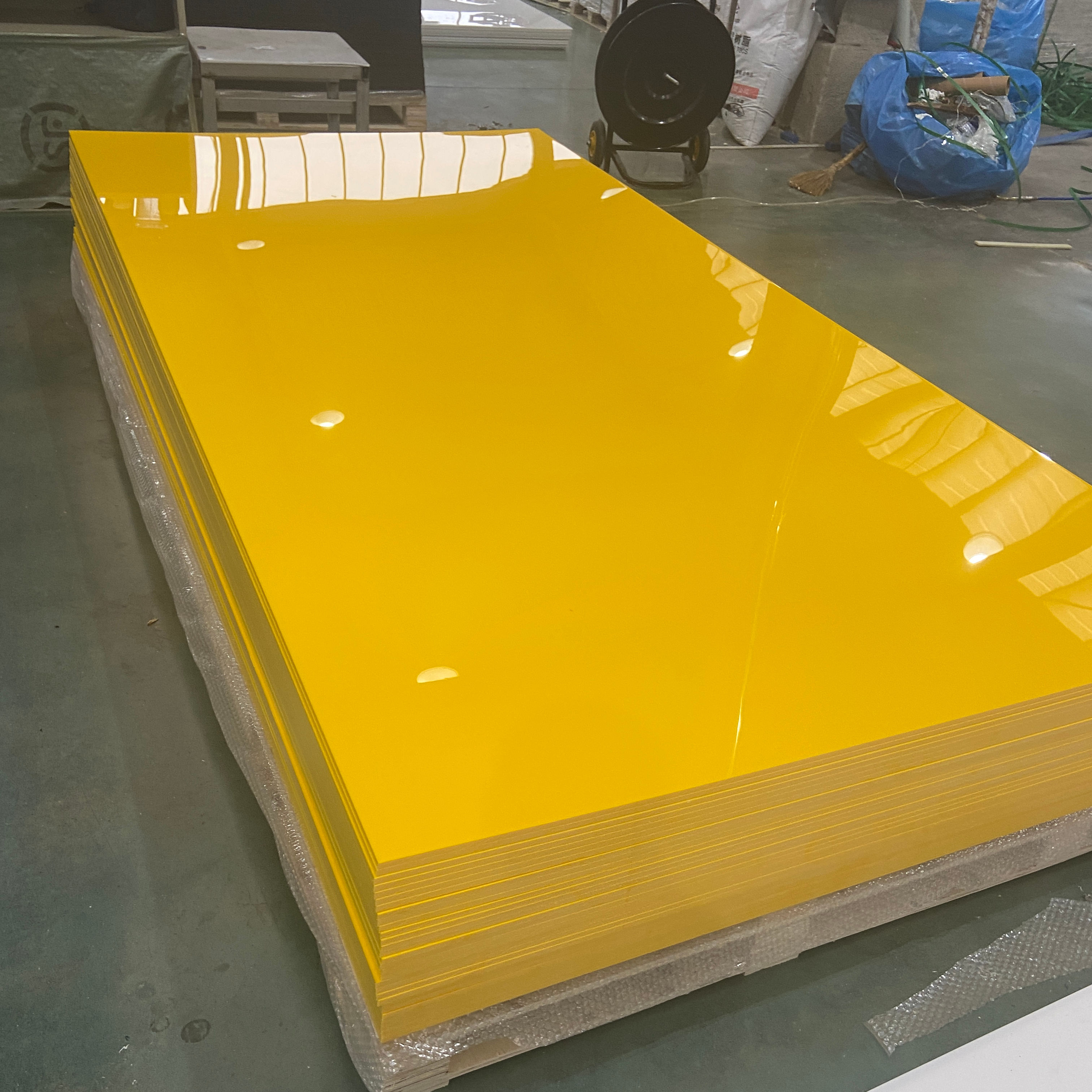

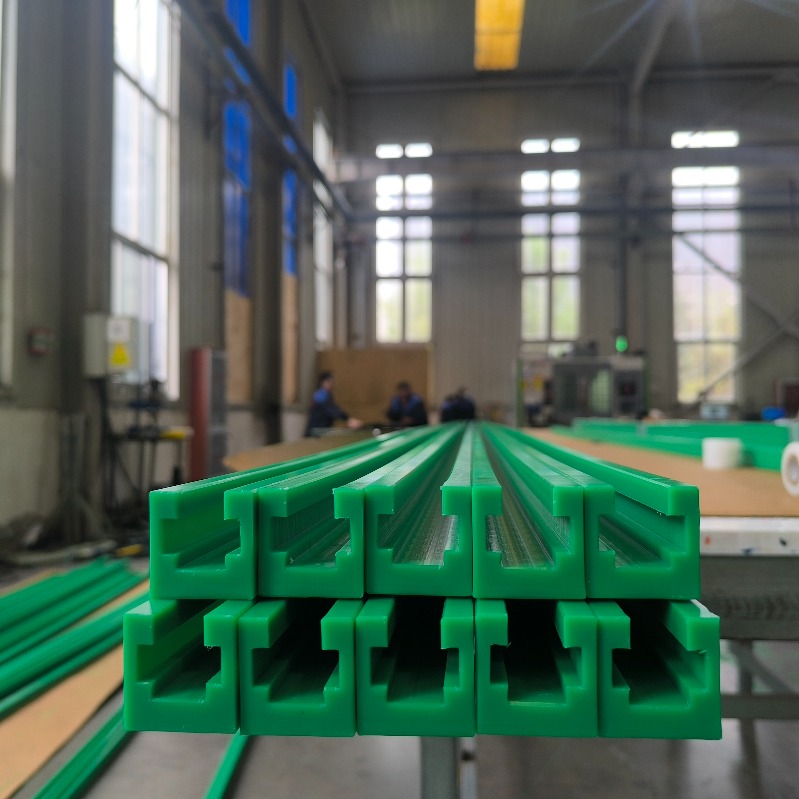

| Virgin | Standard Uhmwpe | Natural/Black/Green/Colours |

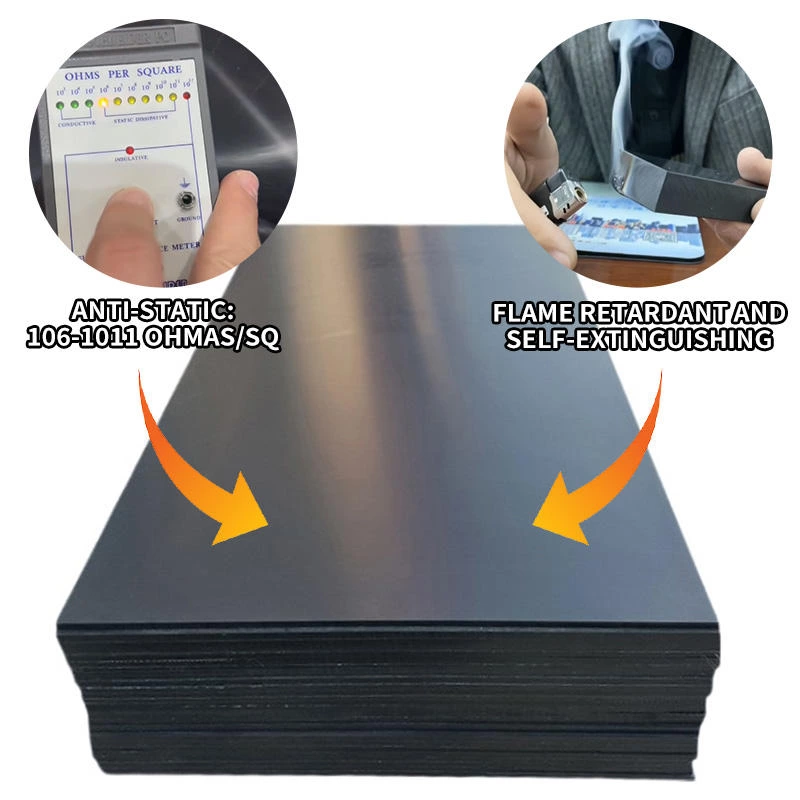

| Anti-Static | Reduces Static Build-up,10⁶ _10¹¹ ohms/sq Surface Resistivity | Black |

| Reprocessed | Eco-friendly And Eco Benefit | Black |

| Uv-Stabilized | Formulation For Outdoor Application | Black |

| Flame Retardant | Flame Retardant And Self-Extinguishing | Black |

| Borated Uhmwpe | Boron Loaded For Neutron Shielding Purposes | Black |

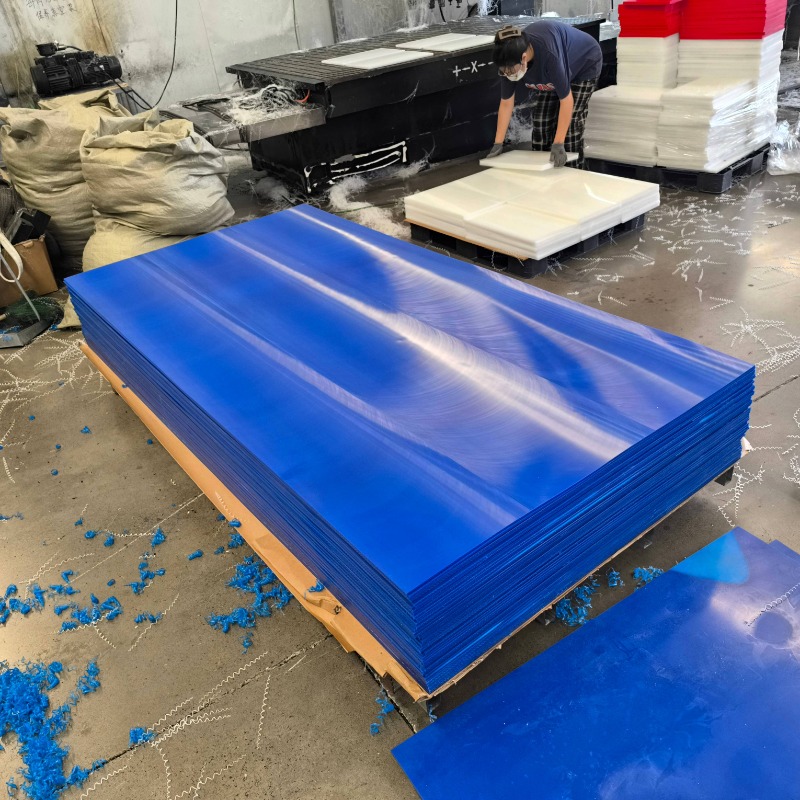

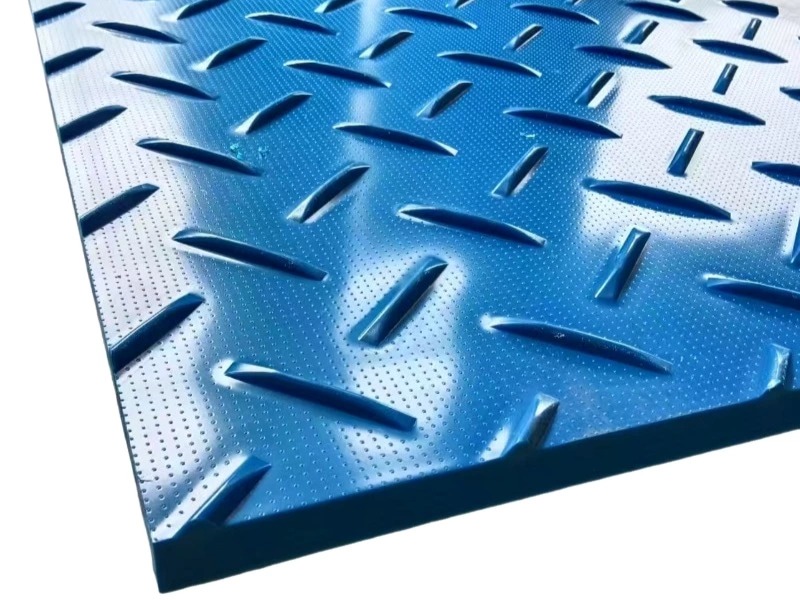

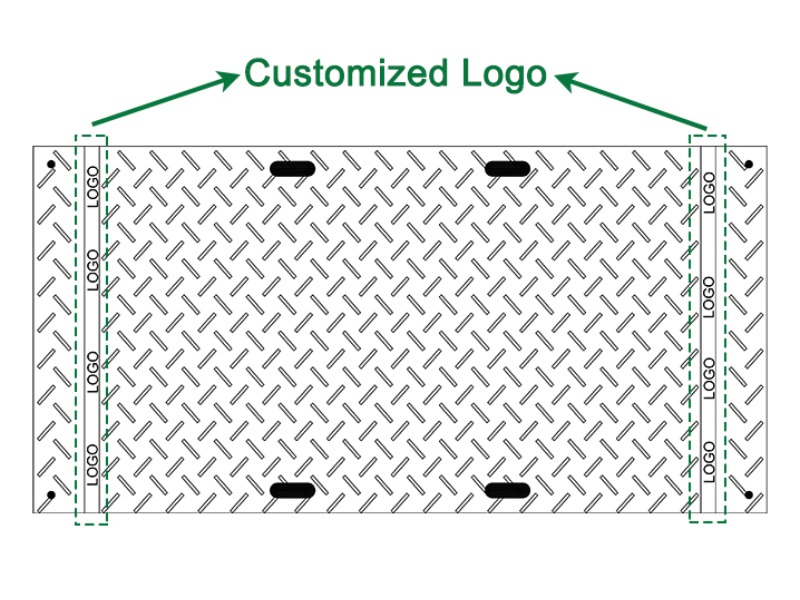

| Marine Grade | Low Friction,Excellent Impact Strength And Good Wear Resistance | Black/Yellow/Blue/Colours |

| Lining Grade | Ideal Material For The Bulk Material Handling And Mining Industry | Black/Blue/Grey/Natural |

| Tech | MoS2 Added For Improving Wear Resistance And Sliding Properties | Grey-Black |

| Oil Filled | Reduced Coefficient Of Friction | Grey |

| Glass Filled | Superior Wear Resistance And Dimensional Stability | Blue |

| Metal Detectable | Metal Detectable For Food Processing | Blue |

| Rubber Backed | Rubber Backing Allows The Use Of Adhesives | - |